Concha servo automática

Marca :Daseon

Origem do produto :China

Tempo de entrega :30 dias

Esta concha servo, com tecnologia avançada, desempenho confiável e design inteligente, é confiável por empresas de fundição sob pressão. Seja para peças automotivas, eletrônica 3C ou maquinário industrial, ela melhora a qualidade da fundição e reduz custos.

In the die casting production process, the automation level of the ladling process significantly impacts production efficiency, product quality, and operational safety. Our meticulously crafted servo ladle deeply integrates advanced technologies and practical designs, targeting the pain points of traditional ladling. With eight core advantages, it has become essential equipment for die casting enterprises to boost competitiveness, redefining industry automation standards.

1.Fully Automated Operation for Seamless Production

2. Servo Drive + RV Deceleration for Stable, Accurate Operation

Equipped with an independent servo motor and RV deceleration drive system, the servo ladle delivers excellent performance. Whether in fast movement or precise positioning, it maintains stability, enhancing efficiency and accuracy compared to raditional equipment. This ensures every ladling action supports high-quality die casting formation, showcasing the servo ladle’s superior operational advantages.

3. Five-Link Structure Design for Spill-Free Molten Aluminum Transfer

4. Stepless Ladle Volume Adjustment for Flexible Operation

5. Mitsubishi PLC Programming Control for Smart Functions

6. Visual Operation Interface for Easy Fault Detection

7. Multiple Safety Protections for Secure Production

8. High-Quality Components for Exceptional Durability

Key components use high-temperature-resistant bearings, ensuring stability in harsh environments. The non-ceramic insulated probe is more durable than traditional designs, reducing replacement frequency and maintenance costs. These durable elements guarantee the servo ladle’s long-term reliable performance.

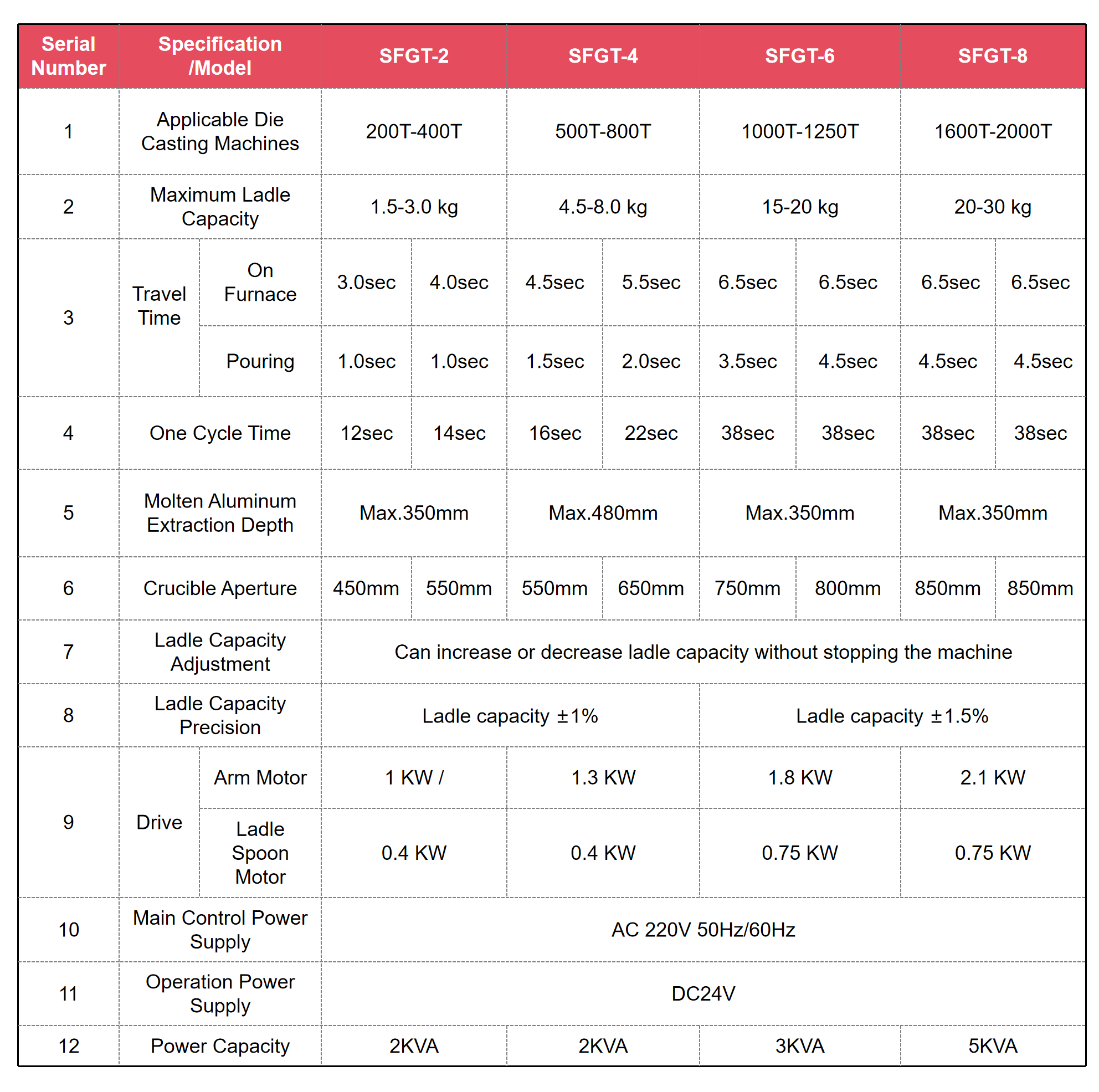

PARAMETER